Products >> Hollow Fiber UF Membrane >> Pentair X-Flow UF Membrane Module

Pentair AQUAFLEX HP UF Membrane

- Product No.:22E1FL895H

AQUAFLEX HP

ARTICLE CODE : 22E1FL895H

General Information

The Aquaflex 64 modules have the following general properties and characteristics:

- Hydrophilic membrane composed of a blend of polyvinylpyrrolidone and polyethersulfone

- A nominal pore size of 20 nm

- Structure asymmetric/microporous

- High performance and a very good anti fouling behaviour

- Typical permeate quality SDI<3, turbidity <0,1 NTU

- Membrane filtration provides 99.9999% (LOG6) reduction of bacteria (Pseudomonas diminuta) and 99.99% (LOG 4) reduction of virus (MS2 colifages) by mechanical means. EPA Est. No. 090374-NLD-001

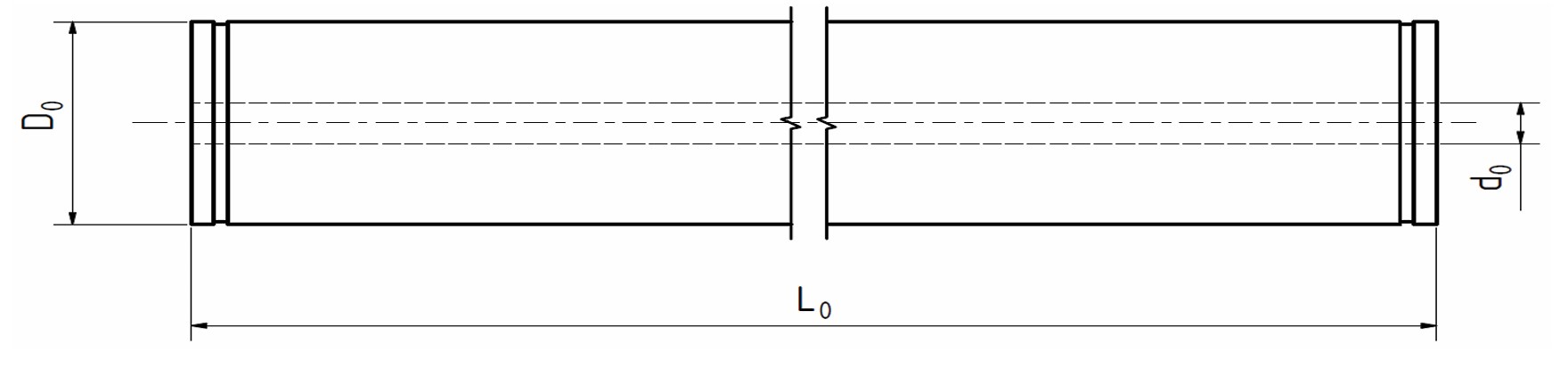

Module Dimensions

|

|

|

|

|

|

|

|

|

|

Physical and Operating Specifications

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

36 × v gpm |

|

|

|

|

|

|

(v) in m/s [ft/s]

Operation guidelines

Backwash water should be free of particulates and should be of UF permeate quality or better.

Backwash pumps should preferably be made of non-corroding materials, e.g., plastic or stainless steel. If compressed air is used to pressurize the backwash water, do not allow a two-phase air/water mixture to enter the element.

To avoid mechanical damage, do not subject the membrane module or element to sudden temperature changes, particularly decreasings. Bring the module or element back to ambient operating temperature slowly (max. value 3 °C/min).

Storage

New membrane modules can be stored as supplied in the original packaging. The membrane elements contain an aqueous preservation solution of glycerine (20wt%) and sodium metabisulfite (1wt%).

Membrane modules should be stored in a dry, normally ventilated place, away from sources of heat, ignition and direct sunlight. Store between 0 and 40 °C.

The membrane modules should not be subjected to any freezing temperatures.

Shelf life is a maximum of 6 months for unused modules in unopened packaging under correct storage conditions after transfer of ownership for X-Flow B.V. to the Client. After the maximum period of 6 months all warrantees are null and void unless otherwise agreed in writing between the parties.

After use, the UF membrane modules need to be stored wet at all times.To avoid biological growth during shutdowns or storage, wet membranes could be treated with a compatible biocide. The membrane is compatible with many common disinfecting agents or biocidal preservatives.

Typically for short-term shutdowns (1 – 7 days), a daily backwash with UF permeate quality water for 30 seconds at 215 lmh, should be adequate for bacteria control. Before start of the shutdown period, the modules must be cleaned by a standard Chemical Enhanced Backwash (CEB).

In case of long-term storage (> 7 days), membranes should be disinfected. The membranes should be cleaned using a CEB before the disinfection step is carried out. For disinfection, a 0,5% sodium metabisulfite solution can be used. In both short and long term storage situations, the modules should remain filled with storage solution.

From EN 1516

Notice:

If your customer insists existing brand, please contact Pentair or its distributors.

If you and your customer accept economical & quick-delivery equivalent of similar or better performance with same warranty, kindly send us an inquiry now.

Products Category

Contact Us

Name: International Sales Dept.

Tel: +86-27-8673 0002

Fax: +86-27-8732 0476

E-mail: inquiry@tanaltech.com

Add: 4th Floor, Baofeng Ages, 1045 Jiefang Blvd, Qiaokou District, Wuhan, Hubei Province, 430030, China

Mail inquiry

Mail inquiry