Products >> Industrial RO Element >> DuPont DOW RO Element

DuPont DOW FilmTec RO Membrane SW30-4040

- Product No.:SW30-4040 (12082966)

Dercription

Improved FilmTec™ SW30-4040 Reverse Osmosis Elements offer the highest productivity while maintaining excellent salt rejection.

• FilmTec™ SW30-4040 Membrane Elements have the highest flow rates available to meet the water demands of both sea-based and land-based desalinators.

• FilmTec™ SW30-4040 Elements may also be operated at lower pressure to reduce pump size, cost and operating expenses.

• Improved FilmTec™ SW30-4040 membrane combined with automated, precision element fabrication result in the most consistent product performance available

DuPont DOW FilmTec RO Membrane SW30-4040 Product Data Sheet

Typical Properties

|

Product |

Part Number |

Applied Pressure psig (bar) |

Permeate Flow Rate gdp (m3/d) |

Stabilized Salt Rejection (%) |

Minimum Salt Rejection (%) |

|

SW30-4040 |

12082966 |

800 (55) |

1,950 (7.4) |

99.7 |

99.5 |

3. For the purpose of improvement, specifications may be updated periodically

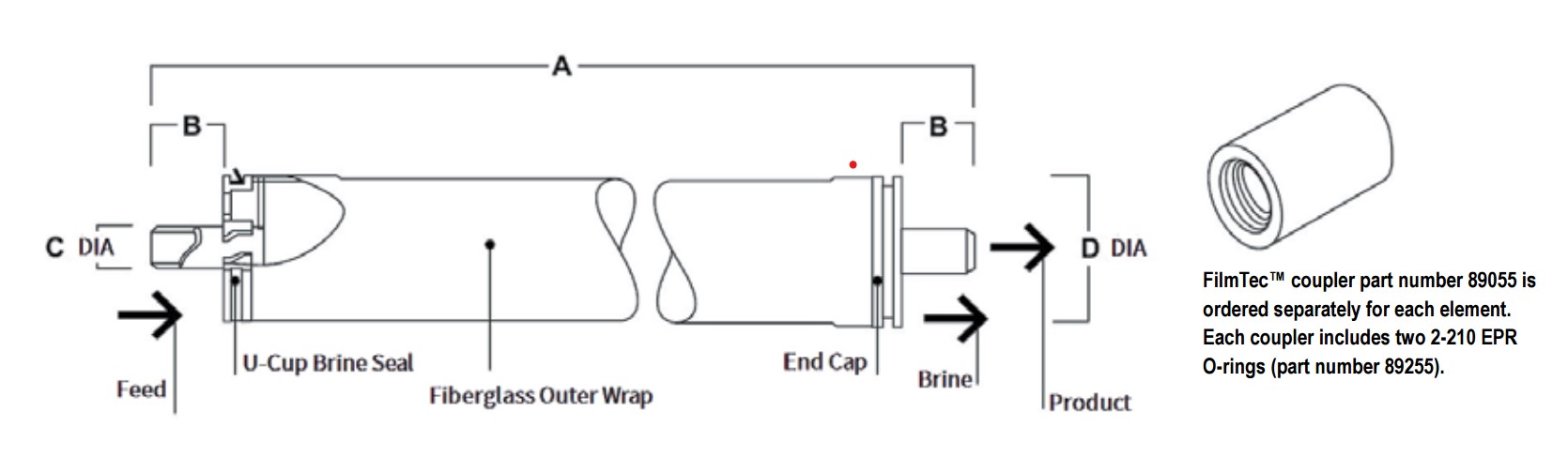

Dimensions

|

Product |

Maximum Feed Flow Rate gpm (m3/h) |

Dimensions – Inches (mm) 1 inch = 25.4 mm |

||||

|

A |

B |

C |

D |

|||

|

Large commercial |

SW30-4040 |

16 (3.6) |

40.0 (1,016) |

1.05 (26.7) |

0.75 (19) |

3.9 (99) |

2. SW30-4040 Element fits nominal 4-inch I.D. pressure vessels.

Operating and Cleaning Limits

|

Membrane Type |

Polyamide Thin-Film Composite |

|

Maximum Operating Temperature |

113°F (45°C) |

|

Maximum Operating Pressure |

1,200 psi (83 bar) |

|

Maximum Pressure Drop |

15 psig (1.0 bar) |

|

pH Range Continuous Operationa Short-Term Cleaningb |

2 - 11 1 - 13 |

|

Maximum Feed Silt Density Index |

SDI 5 |

|

Free Chlorine Tolerancec |

<0.1 ppm |

Important Information

Operation Guidelines

General Information

Notice:

If your customer insists existing brand, please contact DuPont or its distributors.

If you and your customer accept economical & quick-delivery equivalent of similar or better performance with same warranty, kindly send us an inquiry now.

Products Category

Contact Us

Name: International Sales Dept.

Tel: +86-27-8673 0002

Fax: +86-27-8732 0476

E-mail: inquiry@tanaltech.com

Add: 4th Floor, Baofeng Ages, 1045 Jiefang Blvd, Qiaokou District, Wuhan, Hubei Province, 430030, China

Mail inquiry

Mail inquiry