Products >> Hollow Fiber UF Membrane >> DuPont UF Membrane Module

DuPont IntegraTec MB 80

- Product No.:MB 80

DuPont™ IntegraTec™ MB 80

(previously dizzer XL 0.9 MB 80 W)

DuPont IntegraTec MB 80 is a pressurized PES UF module, which offers outstanding physical strength and chemical resistance, effectively eliminating colloidal particulate, bacteria, and viruses. Furthermore, all components in contact with water are corrosion-free, ensuring optimal efficiency throughout the module's lifetime.

DuPont IntegraTec MB 80 Product Data SheetKey Features

- Exceptional physical strength and chemical resistance.

- High colloidal particulate, bacteria and virus log removal rate.

- Excellent filtration permeability.

- Optional coagulation can enhance the removal of algae and organics.

- Open platform design to fit customer built skids.

- Robust materials for long lifetime.

- Easy installation and low maintenance.

- All wetted parts corrosion free

Key Applications

- Municipal drinking water.

- Desalination RO pretreatment.

- Industrial utility water.

- Industrial wastewater reuse.

- Ideal for large systems.

Module Specification

|

Part Number / GMID |

IN-0109 / 12071521 |

|

Mode of Filtration |

In-Out Pressurized |

|

Membrane Type |

Multibore™ |

|

Membrane Material |

PESm |

|

Nominal Membrane Pore Size |

0.02 µm |

|

Module Operating Process |

Dead-end |

|

Housing Material |

PVC-U, white |

|

End Cap Material |

PVC-U, grey |

|

End Cap Coupling Material |

SS (EPDM sealing) |

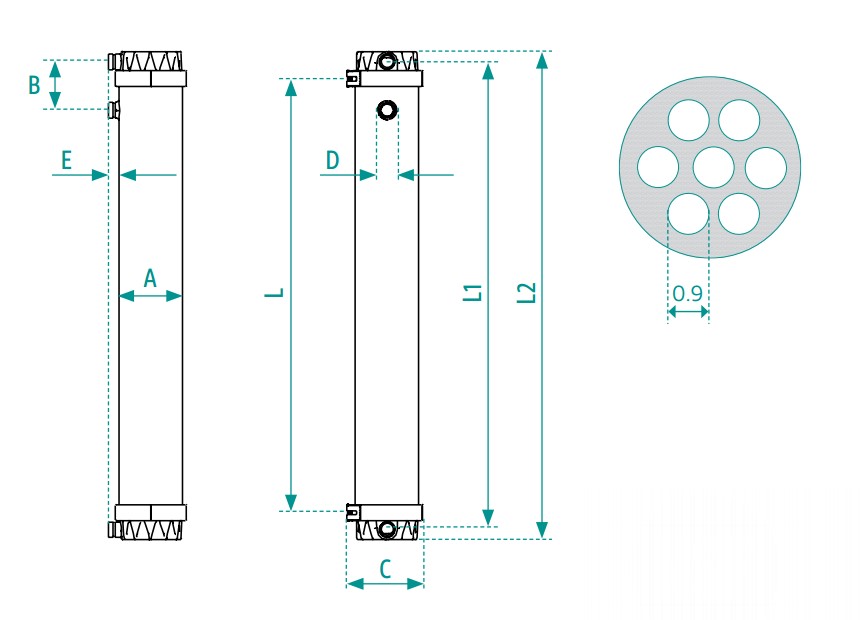

Dimensions

|

Active Membrane Area |

80 m² |

861 ft² |

|

Module Length (L) |

1,720 ± 1.5 mm |

67.7 inch |

|

Distance Top / Bottom Feed Port (L1) |

1,834 ± 3.0 mm |

72.2 inch |

|

Length with End Caps (L2) |

1,914 ± 3.0 mm |

75.4 inch |

|

Module Diameter (A) |

250 ± 1.5 mm |

9.8 inch |

|

Distance Feed Top Port - Filtrate Port (B) |

190 ± 1.5 |

7.5 inch |

|

Outer Diameter End Cap Coupling Maximum (C) |

295 mm |

11.6 inch |

|

Protruding Part of the Port (E) |

40 ± 1 mm |

1.6 inch |

|

Filtrate / Backwash Port (D) |

50.8 mm |

2 inch |

Weight and Volume

|

Shipping Weight |

58 kg |

128 lbs. |

|

Weight Empty |

58 kg |

128 lbs. |

|

Weight Filled |

110 kg |

243 lbs. |

|

Hold-Up Volume Feed (CIP) |

23 L |

6.1 gal |

|

Hold-Up Volume Membrane Structure (CIP) |

20 L |

5.3 gal |

|

Hold-Up Volume Filtrate (CIP) |

17 L |

4.5 gal |

Suggested Operating Conditions

|

General |

Details |

|

|

Operating Temperature Range |

1 - 40 °C |

34 - 104 °F |

|

Operating pH |

3 - 11 |

|

|

Cleaning pH |

1 - 13 |

|

|

Typical Filtration TMP |

0.1 - 0.6 bar |

1.5 - 8.7 psi |

|

Typical Backwash TMP |

0.3 - 2.0 bar |

4.4 - 29.0 psi |

|

Backwash Flux |

230 L/(m²h) |

135 gfd |

|

Backwash Flow |

18.4 m3h |

81.0 gpm |

Operating Limits (Maximum)

|

Rate of Temperature Change |

5 °C/min |

9 °F/min |

|

Inlet Pressure (20 - 40 °C) |

5 bar |

73 psi |

|

Rate of Pressure Change |

0.5 bar/sec |

7.3 psi/sec |

|

Filtration TMP |

1.5 bar |

22 psi |

|

Backwash TMP |

3.0 bar |

44 psi |

|

Filtration Flux |

180 L/(m2h) |

106 gfd |

|

Filtration Flow |

14.4 m3h |

63.4 gpm |

|

Backwash Flux |

300 L/(m²h) |

176 gfd |

|

Particle Size |

300 µm |

|

|

Exposure NaOCl |

≤ 250,000 ppm x h (at pH ≥ 9.5) |

|

|

Concentration NaOCl |

500 ppm |

|

General Information

- Avoid any abrupt pressure variations during start-up, operation, shutdown, cleaning or other sequences to prevent possible membrane damage. The maximum pressure change allowable is 0.5 bar/s.

- For assembly please refer to the DuPont™ IntegraTec™ Pressurized UF In-Out P Series Modules for Open Platforms Assembly Instructions (Form No. 45-D02231-en).

- If operating limits and guidelines given in this bulletin are not strictly followed, any warranty will be null and void.

- To control biological growth during extended system shutdowns, a storage solution must be introduced into the membrane modules. Detailed information is given in the DuPont™ IntegraTec™ Pressurized UF Out-In Module Preservation Instruction Manual (Form No. 45-D02946-en).

Regulatory Note

- Certified drinking water modules require specific conditioning procedures prior to producing potable water. For operating parameters, please refer to the DuPont™ IntegraTec™ Pressurized UF In-Out P Series Process and Design Guidelines (Form No. 45-D02234-en).

- Drinking water modules may be subjected to additional regulatory restrictions in some countries. Please check local regulatory guidelines and application status before use.

- Flushing needs to be done according to the DuPont™ IntegraTec™ Pressurized UF Out-In Module Rinsing Procedure (Form No. 45-D02947-en)

Notice:

If your customer insists existing brand, please contact DuPont or its distributors.

If you and your customer accept economical & quick-delivery equivalent of similar or better performance with same warranty, kindly send us an inquiry now.

Products Category

Contact Us

Name: International Sales Dept.

Tel: +86-27-8673 0002

Fax: +86-27-8732 0476

E-mail: inquiry@tanaltech.com

Add: 4th Floor, Baofeng Ages, 1045 Jiefang Blvd, Qiaokou District, Wuhan, Hubei Province, 430030, China

Mail inquiry

Mail inquiry