Products >> Hollow Fiber UF Membrane >> DuPont UF Membrane Module

DuPont IntegraTec SFD-2660

- Product No.:SFD-2660

Description

- 0.03 µm nominal pore diameter for removal of bacteria, viruses, and particulates including colloids to protect downstream processes such as RO

- PVDF polymeric hollow fibers for high strength and chemical resistance allows longer membrane life

- Hydrophilic PVDF fibers for easy cleaning and wettability that help maintain long term performance

- Outside In flow configuration for high tolerance to feed solids that helps reduce the need for pretreatment processes

- U-PVC housing, helping to eliminate the need for costly pressure vessels

DuPont IntegraTec SFD-2660 Ultrafiltartion Module Product Data Sheet

Typical Properties

|

|

|

|

Membrane area |

Module volume |

Weight (empty/water filled) |

|||

|

Model |

Type |

Part# |

m2 |

ft2 |

Liters |

Gallons |

Kg/lbs |

Kg/lbs |

|

SFD-2660 |

NSF/ANSI 61 Drinking |

324166 |

33 |

355 |

16 |

4.2 |

25/41 |

55/90 |

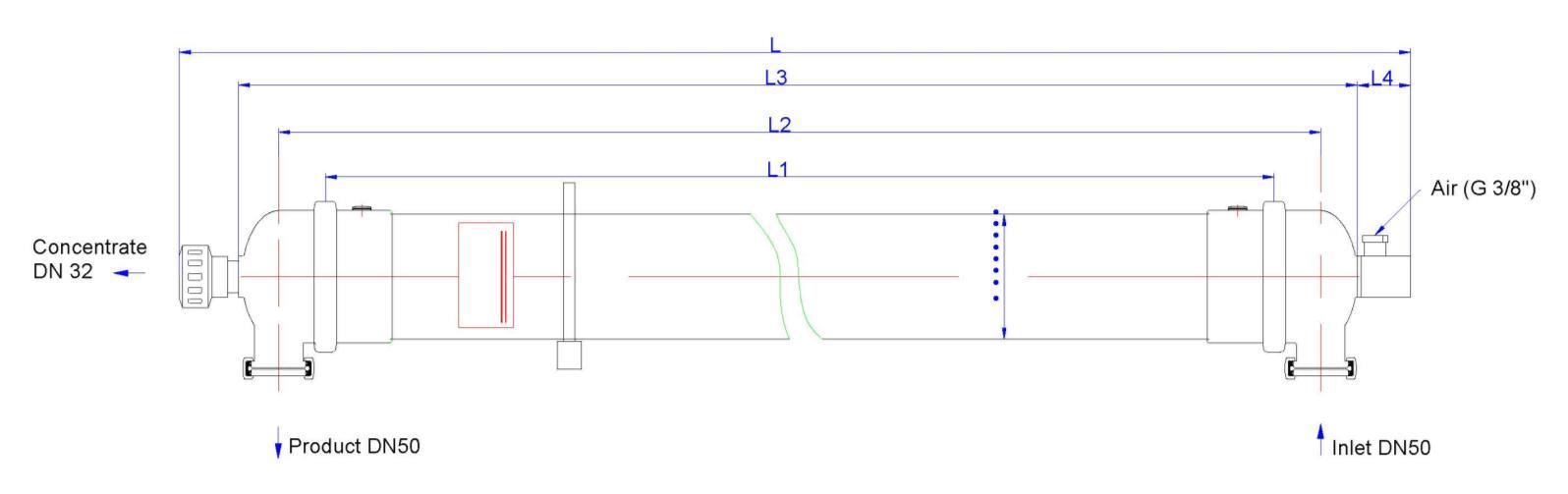

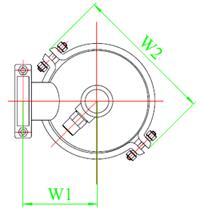

Dimensions SFD-2660 (6-inch diameter)

|

Length |

Diameter |

Width |

|||||

|

Units |

L |

L1 |

L2 |

L3 |

D |

W1 |

W2 |

|

SI (mm) |

1863 |

1500 |

1610 |

1710 |

165 |

125 |

250 |

|

US (inch) |

73.2 |

59.1 |

63.4 |

67.3 |

6.5 |

4.9 |

9.8 |

Operating Parameters

|

|

SI units |

US units |

|

Filtrate Flux @ 25ºC |

40-90 l/m2hr |

24-53 gfd |

|

Flow range per module1 |

1.3-3.0 m3/hr |

5.9 – 13.1 gpm |

|

Temperature |

1-40ºC |

34-104º F |

|

Max. inlet module pressure (@ 20ºC) |

6.25 bar |

93.75 psi |

|

Max. operating TMP |

2.1 bar |

30 psi |

|

Max operating air scour flow |

12 nm3/hr |

7.1 scfm |

|

Max backwash pressure |

2.5 bar |

36 psi |

|

Operating pH |

2 - 11 |

|

|

NaOCl (max.) |

2,000 mg/L |

|

|

Particle size (max.) |

300 µm |

|

|

Flow configuration |

Outside in, dead end flow |

|

|

Expected filtrate turbidity |

≤0.1 NTU |

|

|

Expected filtrate SDI |

≤2.5 |

|

Important information

Before initiating system start-up procedures, membrane pretreatment, installation of the membrane modules, instrument calibration and other system checks should be completed.

Operation guidelines

Avoid any abrupt pressure variations during start-up, shutdown, cleaning or other sequences to prevent possible membrane damage. Flush the ultrafiltration system to remove shipping solution prior to start-up. Remove residual air from the system prior to start up. Manually start the equipment. Depending on the application, filtrate obtained from initial operations should be discarded.

General information

- If operating limits and guidelines given in this bulletin are not strictly followed, the limited warranty will be null and void.

- To prevent biological growth during extended system shutdowns, it is recommended that storage solution be injected into the membrane modules.

Product Stewardship

DuPont has a fundamental concern for all who make, distribute, and use its products, and for the environment in which we live. This concern is the basis for our product stewardship philosophy by which we assess the safety, health, and environmental information on our products and then take appropriate steps to protect employee and public health and our environment. The success of our product stewardship program rests with each and every individual involved with DuPont products—from the initial concept and research, to manufacture, use, sale, disposal, and recycle of each product.

Customer Notice

Please be aware of the following:

- The use of this product in and of itself does not necessarily guarantee the removal of cysts and pathogens from water. Effective cyst and pathogen reduction is dependent on the complete system design and on the operation and maintenance of the system.

Regulatory Note

NSF/ANSI 61 and 419 certified drinking water modules require specific conditioning procedures prior to producing potable water. Please refer to the Ultrafiltratiom Technical Manua (Form No. 45-D00874-en) flushing section for specific procedures. Drinking water modules may be subjected to additional regulatory restrictions in some countries. Please check local regulatory guidelines and application status before use and sale.Notice:

If your customer insists existing brand, please contact DuPont or its distributors.

If you and your customer accept economical & quick-delivery equivalent of similar or better performance with same warranty, kindly send us an inquiry now.

Products Category

Contact Us

Name: International Sales Dept.

Tel: +86-27-8673 0002

Fax: +86-27-8732 0476

E-mail: inquiry@tanaltech.com

Add: 4th Floor, Baofeng Ages, 1045 Jiefang Blvd, Qiaokou District, Wuhan, Hubei Province, 430030, China

Mail inquiry

Mail inquiry