Products >> Hollow Fiber UF Membrane >> DuPont UF Membrane Module

DuPont DOW SFP-2660 Ultrafiltration Module

- Product No.:SFP-2660

Features

- 0.03 µm nominal pore diameter for removal of bacteria, viruses, and particulates including colloids to protect downstream processes such as RO

- PVDF polymeric hollow fibers for high strength and chemical resistance allows longer membrane life

- Hydrophilic PVDF fibers for easy cleaning and wettability that help maintain long term performance

- Outside In flow configuration for high tolerance to feed solids that helps reduce the need for pretreatment processes

- U-PVC housing, helping to eliminate the need for costly pressure vessels

DuPont DOW SFP-2660 Ultrafiltartion Module Product Data Sheet

Product Specifications

|

|

|

|

Membrane area |

Module volume |

Weight (empty/water filled) |

|||

|

Model |

Type |

Part# |

m2 |

ft2 |

Liters |

Gallons |

Kg/lbs |

Kg/lbs |

|

SFP-2660 |

Pretreatment |

280931 |

33 |

355 |

16 |

4.2 |

25/41 |

55/90 |

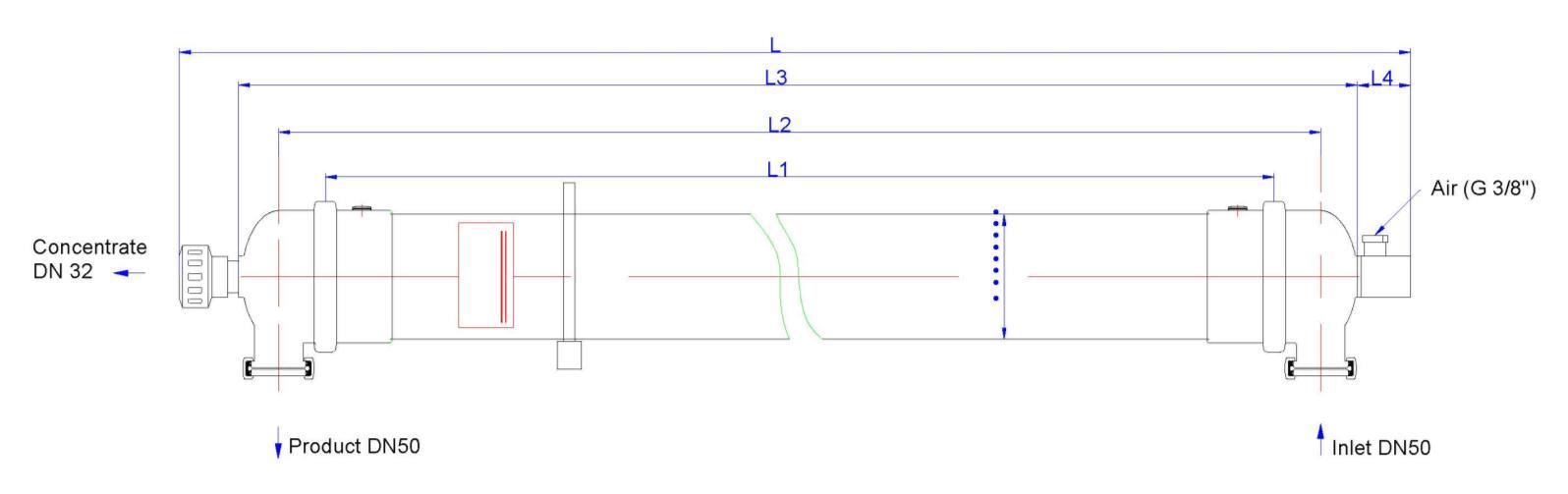

Figure 1 SFP-2660 (6-inch diameter)

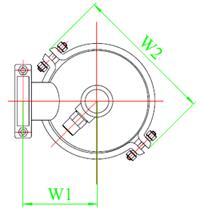

Figure 2

Dimensions

|

Length |

Diameter |

Width |

||||

|

Units |

L |

L1 |

L2 |

L3 |

D |

W1 |

W2 |

|

SI (mm) |

1860 |

1500 |

1610 |

1710 |

165 |

125 |

250 |

|

US (inch) |

73.2 |

59.1 |

63.4 |

67.3 |

6.5 |

4.9 |

9.8 |

Operating Parameters

|

|

SI units |

US units |

|

Filtrate Flux @ 25ºC |

40-120 l/m2hr |

24-70 gfd |

|

Flow range |

1.3-4.0 m3/hr |

5.9 – 17.3 gpm |

|

Temperature |

1-40ºC |

34-104º F |

|

Max. inlet module pressure (@ 20ºC) |

6.25 bar |

93.75 psi |

|

Max. operating TMP |

2.1 bar |

30 psi |

|

Max operating air scour flow |

12 nm3/hr |

7.1 scfm |

|

Max backwash pressure |

2.5 bar |

36 psi |

|

Operating pH |

2 - 11 |

|

|

NaOCl (max.) |

2,000 mg/L |

|

|

TSS (max.) |

100 mg/L |

|

|

Turbidity (max.) |

300 ntu |

|

|

Particle size (max.) |

300 µ |

|

|

Flow configuration |

Outside in, dead end flow |

|

|

Expected filtrate turbidity |

≤0.1 NTU |

|

|

Expected filtrate SDI |

≤2.5 |

|

Important information

Operation guidelines

Avoid any abrupt pressure variations during start-up, shutdown, cleaning or other sequences to prevent possible membrane damage. Flush the UF system to remove shipping solution prior to start-up. Remove residual air from the system prior to start up. Manually start the equipment. Target a permeate flow of 60% of design during initial operations. Depending on the application, permeate obtained from initial operations should be discarded. Please refer to the product technical manual.

General information

To prevent biological growth during system shutdowns, it is recommended that preservative solution be injected into the membrane modules.

Regulatory note

Notice:

If your customer insists existing brand, please contact DuPont or its distributors.

If you and your customer accept economical & quick-delivery equivalent of similar or better performance with same warranty, kindly send us an inquiry now.

Products Category

Contact Us

Name: International Sales Dept.

Tel: +86-27-8673 0002

Fax: +86-27-8732 0476

E-mail: inquiry@tanaltech.com

Add: 4th Floor, Baofeng Ages, 1045 Jiefang Blvd, Qiaokou District, Wuhan, Hubei Province, 430030, China

Mail inquiry

Mail inquiry