Products >> Hollow Fiber UF Membrane >> DuPont UF Membrane Module

DuPont IntegraTec XP 51 IG

- Product No.:XP 51 IG

Features

- Proven XP™ Hydrophilic PVDF Fiber:

– High colloidal particulate, bacteria, and virus log removal rate.

– Excellent filtration permeability.

– Easy cleaning and wettability.

- Optimized Module Design:

– Reduced chemical consumption with maintenance cleanings protocol.

– Robust materials for long lifetime.

– Easy installation and low maintenance.

The DuPont IntegraTec XP 51 IG module is shorter in height, higher in recovery and is suitable for applications where height is a constraint.

– Industrial utility water.

– Industrial wastewater reuse.

– Municipal wastewater filtration.

– RO pretreatment.

Product Specifications

|

|

||||||||

|

|

Part No / GMID |

Mode of Filtration |

Type |

Material |

Pore Size |

Operating Process |

Other Wetted |

|

|

|

|

|

|

|

|

|

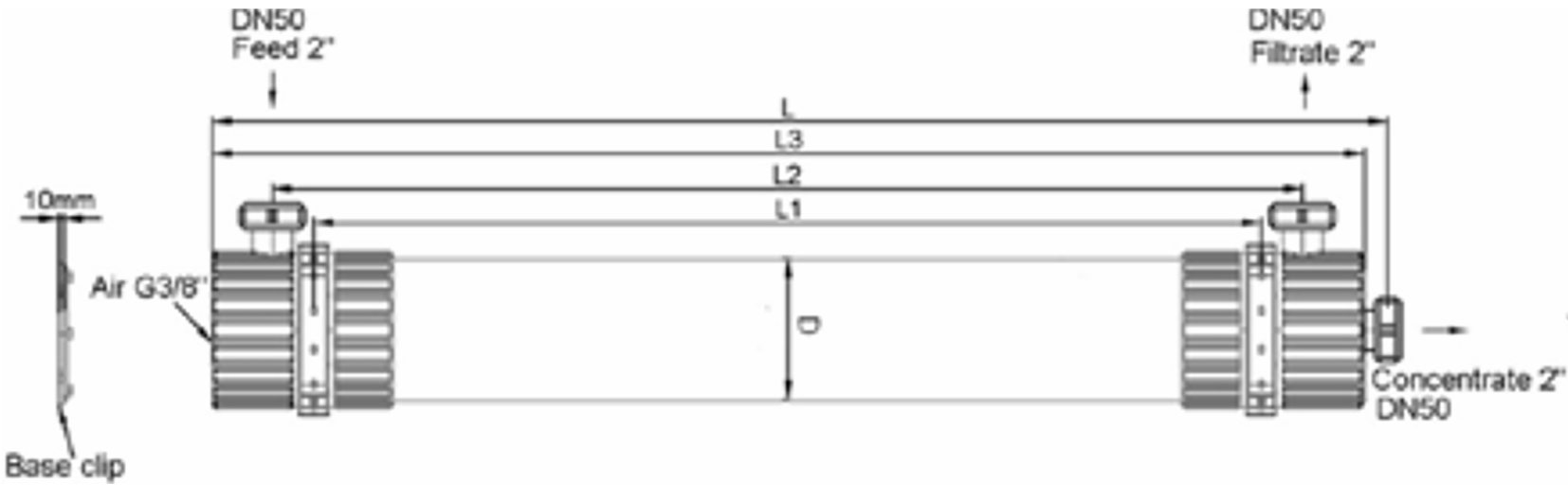

Figure 1

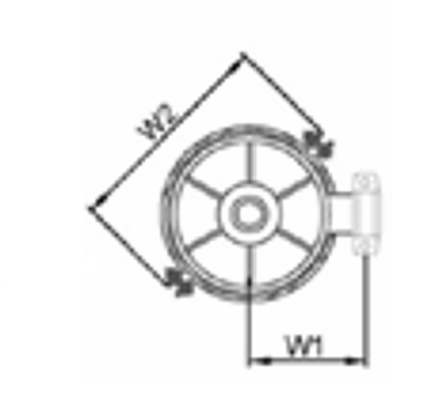

Figure 2

Properties

Dimensions

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Operating Parameters

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Operation guidelines

Please refer to the latest version of the DuPont™ IntegraTec™ PVDF-UF Out-In P Series IntegraPac™ Rack Assembly Manual

General information

If operating limits and guidelines given in this document are not strictly followed, any warranty will be null and void.

To control biological growth during extended system shutdowns, storage solution has to be introduced into the membrane modules.

Regulatory note

Drinking water modules may be subjected to additional regulatory restrictions in some countries. Please check local regulatory guidelines and application status before use.

Notice:

If your customer insists existing brand, please contact DuPont or its distributors.

If you and your customer accept economical & quick-delivery equivalent of similar or better performance with same warranty, kindly send us an inquiry now.

Products Category

Contact Us

Name: International Sales Dept.

Tel: +86-27-8673 0002

Fax: +86-27-8732 0476

E-mail: inquiry@tanaltech.com

Add: 4th Floor, Baofeng Ages, 1045 Jiefang Blvd, Qiaokou District, Wuhan, Hubei Province, 430030, China

Mail inquiry

Mail inquiry